Industrial PLC Programming & Automation Solutions

Transform your industrial operations with custom PLC programming services that enhance efficiency, precision, and productivity across manufacturing, mining, and energy sectors.

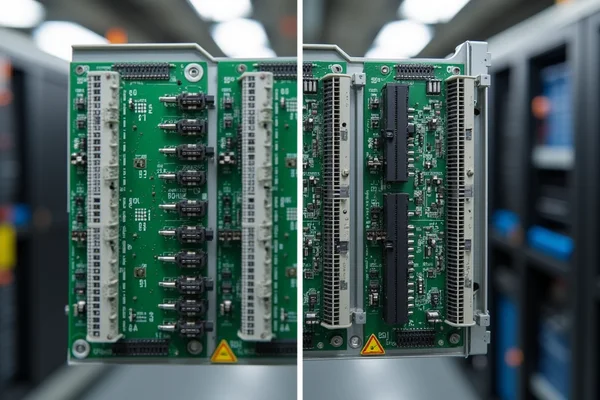

Empowering Industries Through Advanced Automation

Programmable Logic Controllers (PLCs) are the backbone of modern industrial automation, controlling everything from simple machine functions to complex manufacturing processes. At TECG, we specialize in developing custom PLC solutions that streamline operations, enhance precision, and optimize efficiency across various industries. Our comprehensive programming services cover everything from initial design and implementation to integration, troubleshooting, and ongoing support, ensuring your automated systems operate at peak performance throughout their lifecycle.

Our Comprehensive PLC Programming Services

Custom PLC Programming

PLC System Integration

PLC Upgrades & Migrations

Troubleshooting & Debugging

Training & Documentation

SCADA & HMI Integration

Common Issues We Identify

Our comprehensive inspections address these common issues and more, ensuring your property remains safe and efficient.

Industries We Serve

Our PLC programming expertise spans across diverse industrial sectors, delivering tailored automation solutions for specific operational challenges.

Manufacturing

Automate assembly lines, quality control processes, material handling, and packaging operations to enhance throughput and consistency.

Mining

Implement reliable control systems for conveyor networks, crushing equipment, pumping stations, and environmental monitoring.

Energy

Optimize power generation, distribution systems, and renewable energy infrastructure with precision control and monitoring.

Water & Wastewater

Automate treatment processes, pumping stations, filtration systems, and remote monitoring for efficient water management.

Agriculture

Control irrigation systems, climate management, feeding operations, and production monitoring for modern farming operations.

Food & Beverage

Ensure precise process control, maintain quality standards, and implement tracking systems for production and packaging.

Leading PLC Platforms We Support

Our expertise spans multiple industry-standard PLC platforms, ensuring we can work with your existing systems or recommend the ideal solution for your needs.

Allen-Bradley

Industry-leading automation solutions from Rockwell Automation, known for reliability and extensive capabilities.

Key Features:

- ControlLogix/CompactLogix platforms

- Studio 5000 programming

- FactoryTalk integration

- Safety automation solutions

Siemens

Comprehensive automation technology with powerful controllers for diverse industrial applications.

Key Features:

- SIMATIC S7 controllers

- TIA Portal programming

- PROFINET networking

- Industrial security solutions

Mitsubishi Electric

Reliable automation systems with high-speed processing and excellent connectivity options.

Key Features:

- MELSEC iQ-R/iQ-F series

- GX Works programming

- CC-Link IE Field network

- GOT HMI integration

Schneider Electric

Versatile automation solutions with strong focus on energy efficiency and sustainability.

Key Features:

- Modicon M340/M580 PLCs

- EcoStruxure Control Expert

- Ethernet IP networking

- Energy management integration

We can advise on the best solution for your specific business requirements during our assessment.

Benefits of PLC Programming & Automation

Enhanced Productivity

Cost Reduction

Improved Precision

Extended Equipment Life

Enhanced Safety

Scalable Growth

Our PLC Implementation Process

Consultation & Requirements Analysis

System Design & Architecture

Programming & Configuration

Integration & Installation

Testing & Commissioning

Training & Support

Ready to Automate Your Operations?

PLC Programming Trends & Innovations (2025)

Stay at the forefront of industrial automation with these emerging technologies and methodologies

AI-Enhanced Automation

Machine learning algorithms are being integrated with PLC systems to enable predictive maintenance, optimize process parameters in real-time, and identify patterns that human operators might miss.

Edge Computing Integration

Moving data processing closer to the source, edge computing enables real-time decision making without cloud latency, critical for high-speed manufacturing and sensitive processes.

OT/IT Convergence

Traditional operational technology (OT) systems are increasingly integrating with information technology (IT) infrastructure, allowing seamless data flow between production systems and business applications.

Our PLC implementations adhere to current IEC 61131-3 programming standards and incorporate cybersecurity measures that align with IEC 62443 for industrial automation and control systems security.

Our PLC Programming Expertise

Multi-Platform Programming

Industrial Network Specialists

Cybersecurity Focus

Our Certifications & Memberships

Why Choose TECG for PLC Programming

Experienced and Qualified Team

Locally Owned and Operated

Fast and Reliable Service

Transparent Pricing

Customer Satisfaction Guaranteed

Emergency Support When You Need It Most

Ready to Optimize Your Industrial Operations?

Contact TECG today for a consultation on how our PLC programming services can enhance your efficiency and productivity

Request a Quote

Fill out the form below and we'll get back to you as soon as possible

Frequently Asked Questions

Find answers to common questions about our PLC programming services

Can't find what you're looking for? Contact us for more information.